1000MW 150 Tons Heavy Steel Forgings , Customized Generator Rotor Forging

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1000MW 150 Tons Heavy Steel Forgings , Customized Generator Rotor Forging <span sty

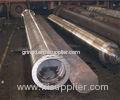

1000MW 150 Tons Heavy Steel Forgings , Customized Generator Rotor Forging

Quick Detail:

1. This open die forging inlcuding generator rotor, rotor forging, steel rotor, rotor part forging for thermal power plant

2. The material of alloy steel (30Cr1Mo1V, 25Cr2Ni4MoV, 30Cr2Ni4MoV, 34CrNi3Mo) is normal for such forgings.

3. The experienced factory makes sure the good quality, good service, short delivery time

Description:

This is customized open die forging, including generator rotor, rotor forging, steel rotor, rotor part forging for thermal power plant. The main material is alloy steel (30Cr1Mo1V, 25Cr2Ni4MoV, 30Cr2Ni4MoV, 34CrNi3Mo) etc.

The manufacturing equipment is 80~185MN hydraulic press, the forging ratio >3,

Smelting Process:EF+LF + VD+VC

The process as follow :Ingot →heat → forging → Heat treatment (Normalizing+ tempering) →

Inspection →rough machining→UT →2th Heat treatment →finishing machining →Inspection

Specifications:

Description | generator rotor, rotor forging, steel rotor, rotor part forging for thermal power plant |

material | alloy steel (30Cr1Mo1V, 25Cr2Ni4MoV, 30Cr2Ni4MoV, 34CrNi3Mo) etc. |

Material standard | ASTM or GB/T3077-1999 |

Dimension | Min. 8000KW, Max. 1000MW |

Weight | Max. 250 ton |

Smelting Process: | EF+LF + VD |

Process | Ingot→heat → forging → Heat treatment (Normalizing+ tempering) → Inspection → |

UT standard | ASTM B or others |

Applications:

The generator rotor forgings are used for the thermal power plant device as generator rotor, rotor forging, steel rotor, rotor part forging for thermal power plant. The main material is alloy steel (30Cr1Mo1V, 25Cr2Ni4MoV, 30Cr2Ni4MoV, 34CrNi3Mo) etc.

Competitive Advantage:

Quality control and management to the whole produce process, including ingot smelting, forging, heat treatment, machining and strictly final inspection prior to delivery.

Excellent product quality and service, competitive price, “in-time” delivery

Why us?

1. Short production time, “in-time” delivery;

2. We can provide the steel forgings whatever size, material or type as per your requirements;

3. Good quality and competitive price

Zhongzhong company has much experience in the generator rotor forgings. The manufacturer is Chinese stated powerful enterprise.

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

China Steel Online Market [China (Mainland)]

Business Type:Manufacturer

City: Beijing

Province/State: Beijing

Country/Region: China (Mainland)